The working platform is a device used in conjunction with construction scaffolding with the function of spanning across construction scaffolding, helping workers to move easily on the scaffolding. The working platform is also known by a few other names such as scaffolding platform, operating platform.

Any project requires an elevated working platform from construction to completion. Therefore, it is required that this equipment must have good load-bearing capacity to support materials and workers as well as durability. However, finding a unit that fully meets the above criteria has never been simple.

Working floor sizes vary depending on the contractor's needs. However, they include common parameters such as:

Length: 3000mm, 2500mm, 2000mm, 1800mm, 1600mm, 1500mm…

Width: 380mm, 360mm, 300mm,…

Thickness: 2.0ly, 1.4ly, 1.2ly, 1.0ly.

Type: Oil painted, galvanized, zinc dipped, ribbed, punched.

Safety equipment: regular hook, hook with lock at both ends.

The floor surface is perforated to create friction to avoid slipping during operation.

The floor is always supported by sturdy tie bars.

Basic types of working floors?

Depending on the shape and use, people divide the elevated working platform into types such as:

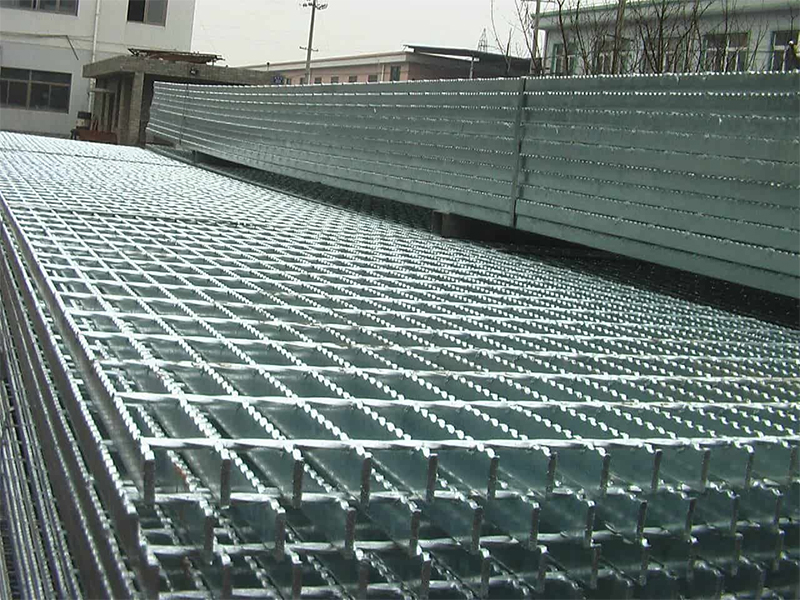

Mesh working platform: This is a device with diamond-shaped steel mesh cells. Depending on the scale of the project, you choose the appropriate working floor size.

Traditional working platform: This is also a commonly used device in many projects. With advanced CO2 welding technology, it brings certainty, safety and efficiency during construction.

Tendon & punching floor: This will be a device that is highly appreciated in many aspects. Thanks to the ribbed and perforated design, it prevents slipping and effectively drains water. Above all, they are also durable over time thanks to guaranteed production materials and can be reused many times.

Things to note when looking for quality Operation Floors

To ensure construction progress as well as high safety, equipment that meets quality standards is required. In particular, when working on the floor, you need to pay attention to the following characteristics:

The operating platform must meet the load capacity according to standards and design.

Prioritize galvanized working floors because they possess good resistance to oxidation and rust.

Easy to install, does not warp during use.

Possesses good anti-slip ability.

The hole in the floor must prevent materials from passing through.

The parts on the floor must be smooth and hard, without the risk of causing injury to people.

There must be a point to avoid water stagnation on the floor.

With its experience and knowledge, Hong Chau Mechanical has gone into processing operating floors and providing the market with products that meet high quality standards. The products we provide all meet the designed load capacity, ensuring absolute safety. Advanced machinery system produces consistent quality, no warping during use.

For further details please contact:

HONG CHAU MECHANICAL MANUFACTURING - TRADING CO., LTD

Address: Lot H12-H15A, Road No. 3, Le Minh Xuan Industrial Park, Dist. Binh Chanh, HCMC

Phone: 028.37 665 363 - 028.37 660 783

MST: 0302394801 - Date of issue: August 21, 2001 - Place of issue: HCMC Department of Planning and Investment

Hotline: Mrs. Phung: 0903 90 99 18

Email: SP_hongchau@cokhihongchau.com

Email: sp.cokhihongchau@gmail.com

Website: www.cokhihongchau.com - www.cokhihongchau.com.vn